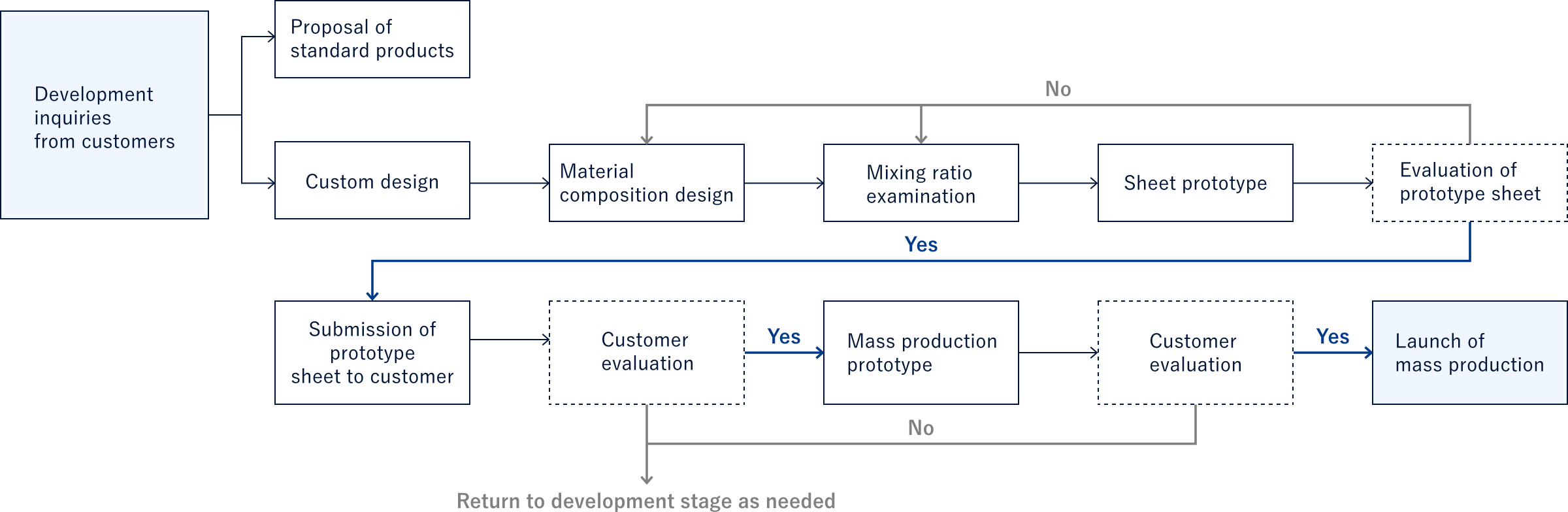

EXAMPLES OF PRODUCTS AND PROTOTYPES

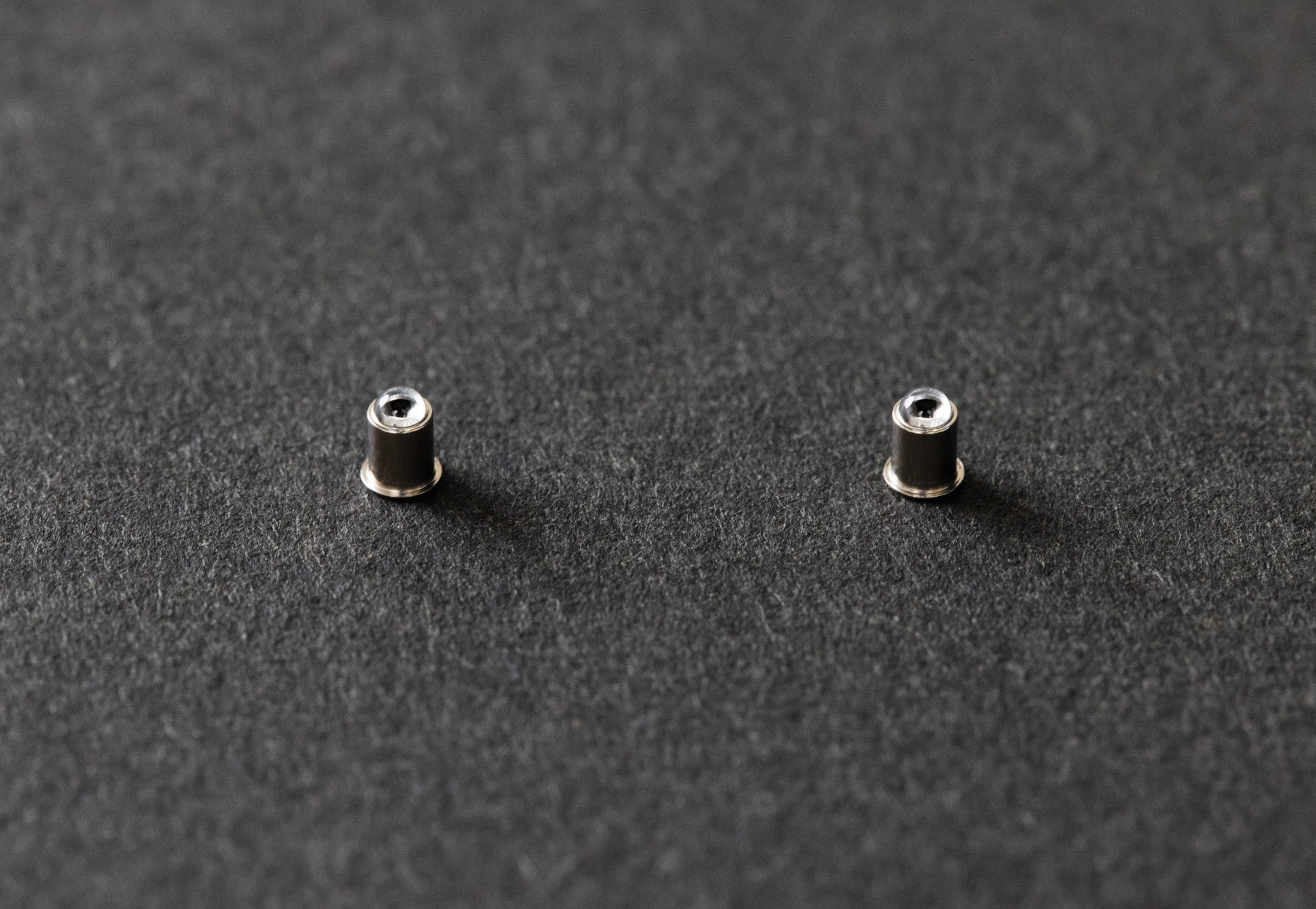

Mini PKG (flat type)

Achieves the joining of small windows by an original process

Metal can shape: round, square

Window material size: around 2 square millimeters

01

Blow processing (including mold design)

Press working

Tube pulling

Lathe manufacturing

In addition to processing glasses by the methods described above, we also have abundant experience in air-sealing processing of metal and glass, such as embedding metal terminals. We also have a lot of design know-how regarding the sealing shape, and it is possible to realize the air-sealing process with excellent strength because of the design to reduce applied stress. By taking advantage of technologies such as ring seals that join ring-shaped metal and cylindrical glass, or disc seals that join ring-shaped metal and disk-shaped glass, we provide products for medical, analytical, and infrastructure-related equipment requiring high vacuum.

X-ray tubes for medical or industrial usage

Image intensifier tube

Enclosure for vacuum interrupter

Vacuum container for electron tubes

Glass stem

Yamamura Photonics is also focusing on inheriting glass processing technology. We are working to continuing the glass business and reinforcing the production system in the future. Also, we are working on raising the skills of existing technicians and making them multi-skilled mainly through OJT, not only training new technicians. We are continuously building a work environment where we can actively respond to new inquiries.02

Direct joining of glass and metal

Joining using low melting point sealing glass

Joining using Hybrid resin adhesive

| HERMETICITY | STRENGTH | MATCHING OF CTE | JOINING TEMPERATURE | |

|---|---|---|---|---|

| DIRECT SEALING | ○ | ○ | necessary | over 800℃ |

| SEALING GLASS WITH LOW MELTING POINT | ○ | ○ | necessary | 400~550℃ |

| PDMS HYBRID MATERIAL | △ | △ | unnecessary | 180〜250℃ |

Medical electron tubes

Viewing ports, etc.

TO-Cap

Glass LID, etc.

CaF2 Cap, etc.

03

OCA (Optical Clear Adhesive)

Thermal conductive sheet (insulation type)

04

Mini PKG (flat type)

Achieves the joining of small windows by an original process

Metal can shape: round, square

Window material size: around 2 square millimeters

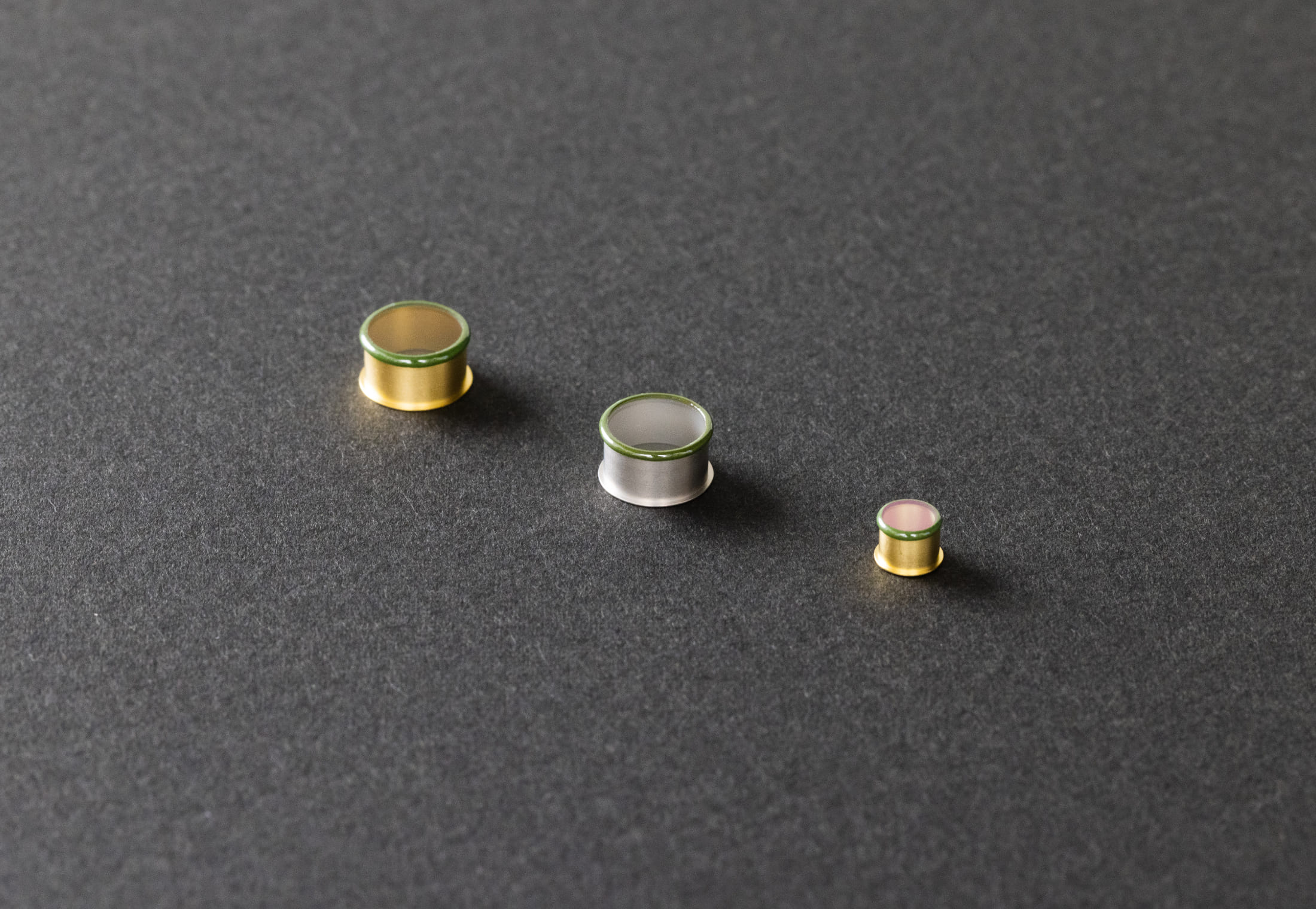

Mini PKG (fused lens type)

Reduces diameter by directly joining the lens and metal can

Metal can shape: round

Lens diameter: φ1.6 mm ~

Side-sealed PKG

Achieves maximum inner height of windows by sealing the side of the window material with suppressing the PKG height.

Metal can shape: round

PKG size: φ5.6 mm ~

Window diameter: φ9-1.2 mm

05

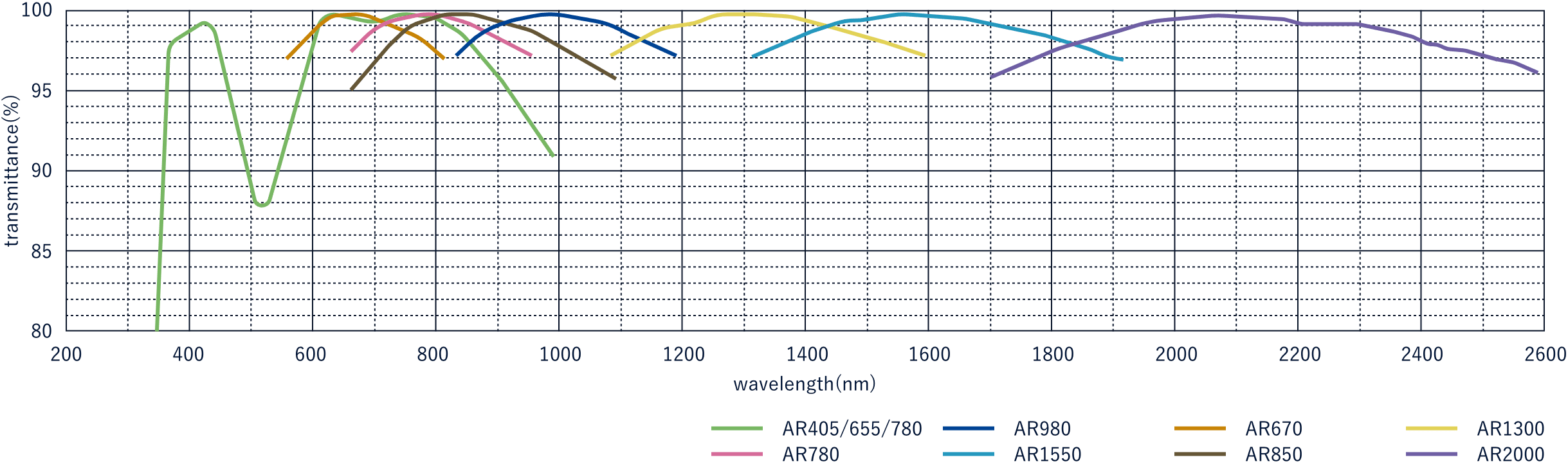

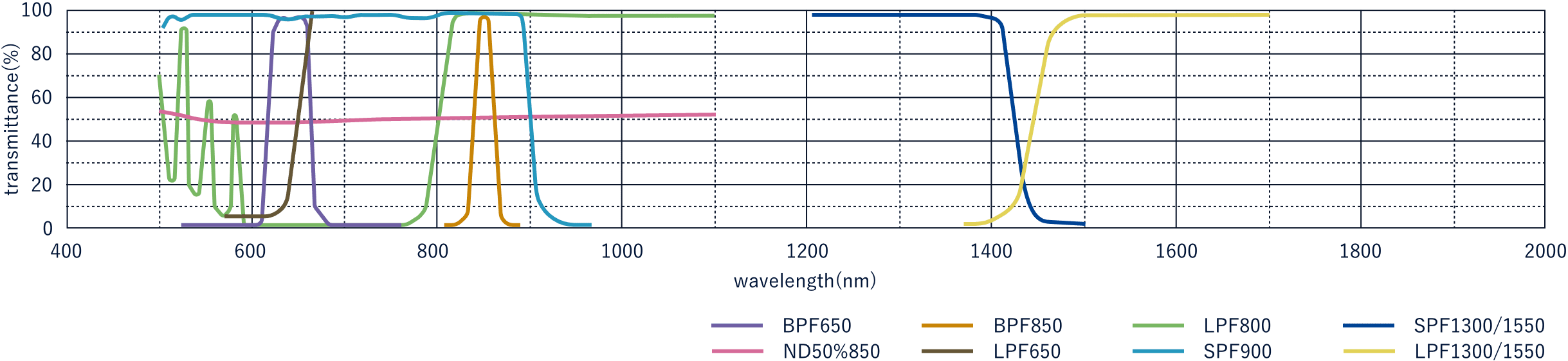

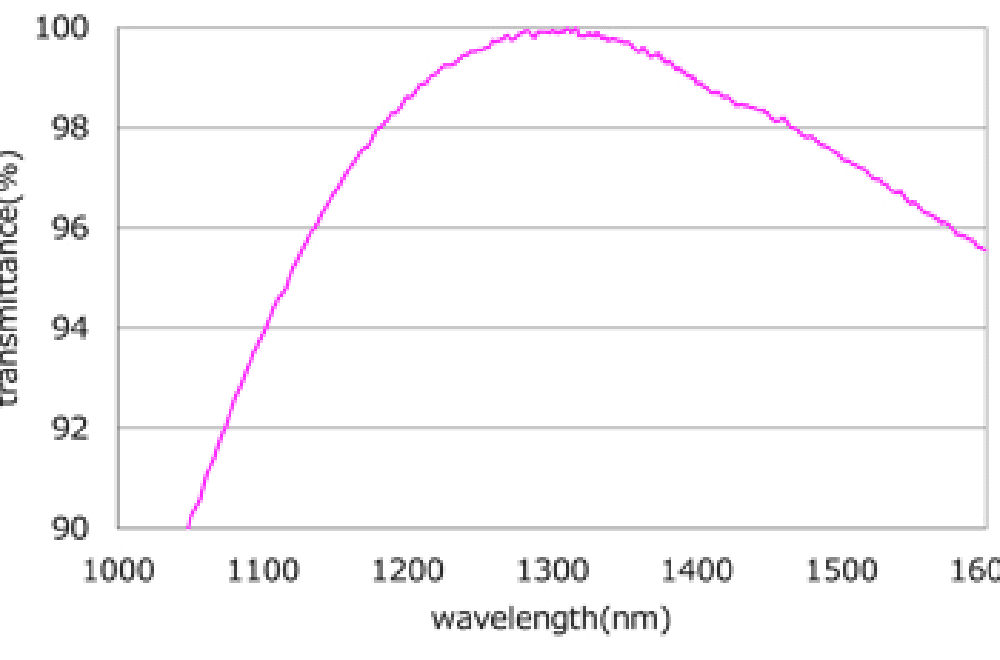

Optical devices have various applications, including sterilizations, lightings, images, optical communications, and sensors. Yamamura Photonics supports custom designs of optical coatings to propose the most suitable products for each application from ultraviolet to mid-infrared. After specifying the wavelength band to be used and the required transmittance or reflectance, we will design the optical coating and propose the simulation result of the transmittance or reflectance. In addition to anti-reflection (AR) coating in ultraviolet, visible light, and near-infrared, we can also propose various mirror coatings and bandpass filters. We can form an AR film on lenses, caps, and other specially shaped parts in addition to flat plates. And, we also support jig design for the coating process, so please feel free to contact us when considering custom coating design.

Anti-reflective coat (AR)

Various mirrors

Various edge filters and bandpass filters, etc..

06

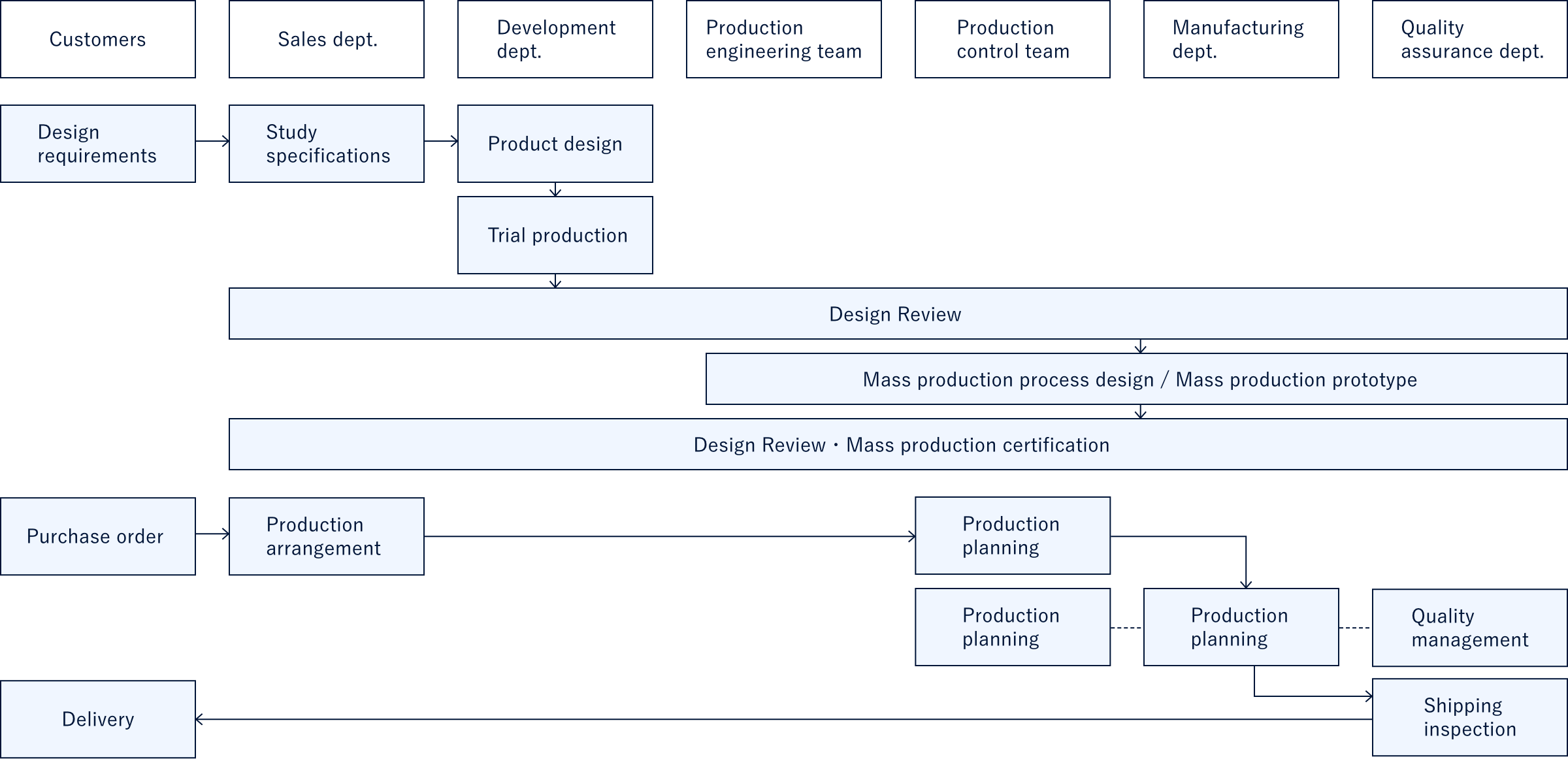

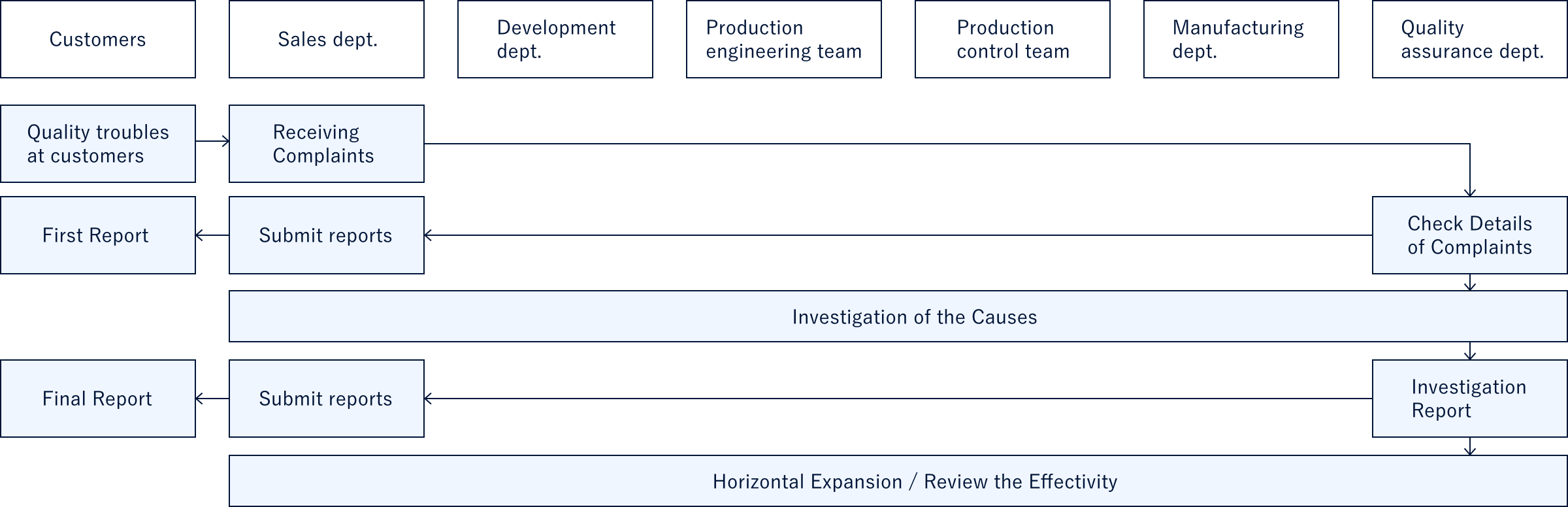

Products of Yamamura Photonics are widely used not only in Japan but also around the world.

In response to daily inquiries from customers, such as requests for new products and quality improvement, we have built a system that enables each department to work closely together to respond to them speedily, and we are working to realize detailed support.

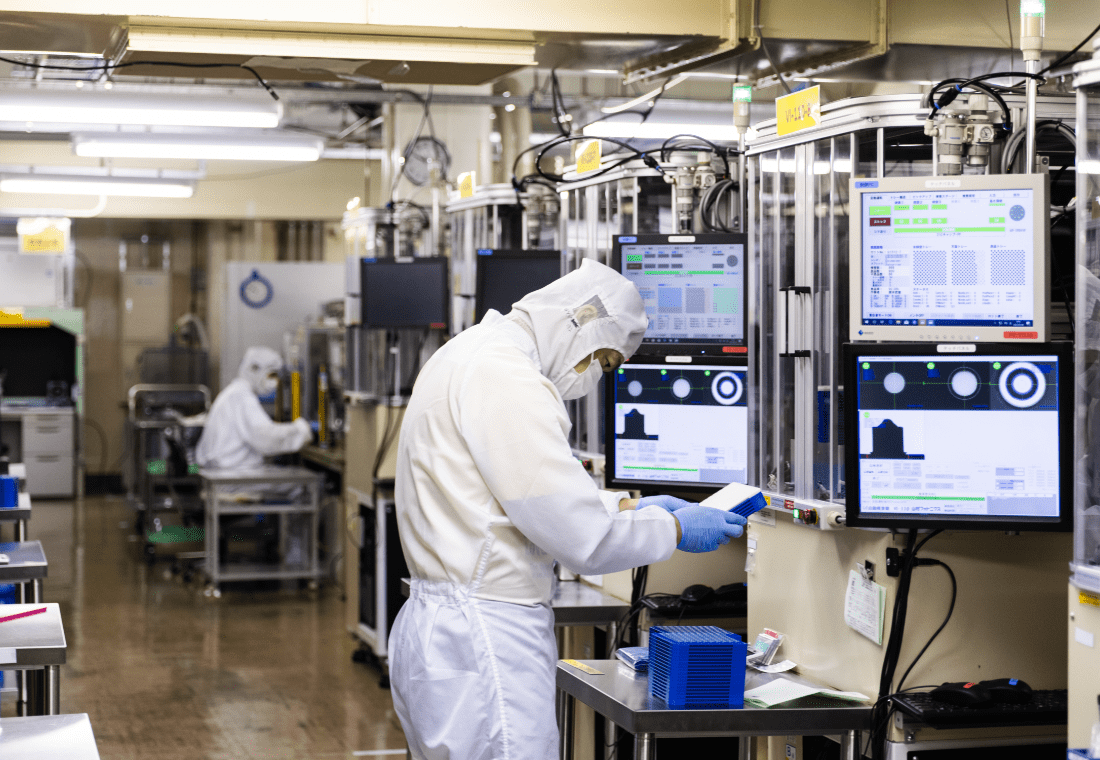

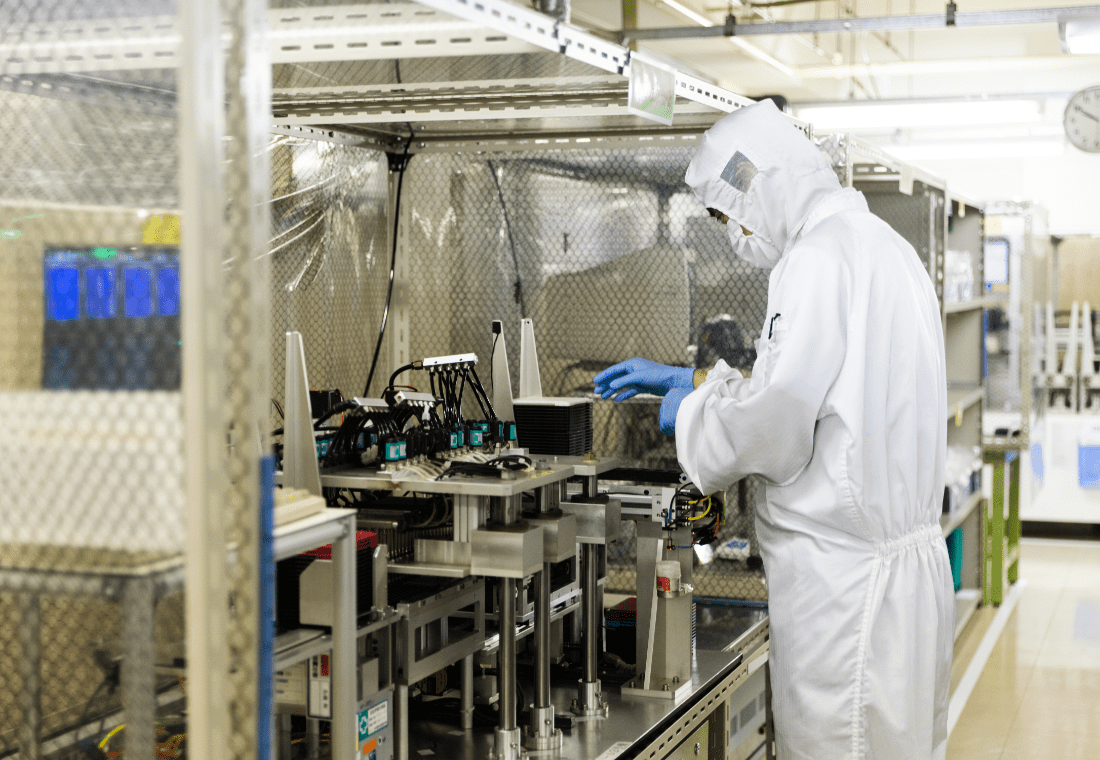

The production process history is essential information in dealing with quality problems and in daily quality improvement activities. Yamamura Photonics has built an original system that can trace from the receipt of parts to the shipment of products and is ready to retrieve the data accumulated for each process.

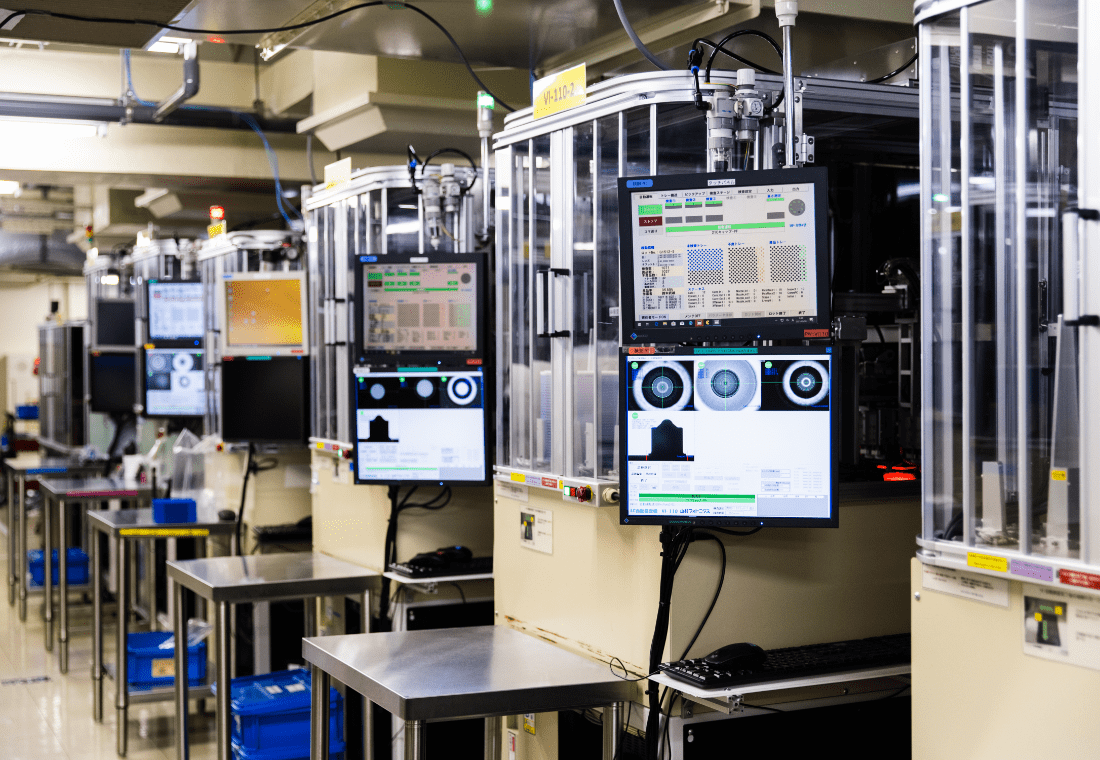

Yamamura Photonics has an inspection system for each process to maintain product quality. Especially in the manufacturing process of small products such as optical parts, we have introduced multiple automatic inspection machines and inspected all products to guarantee their quality.

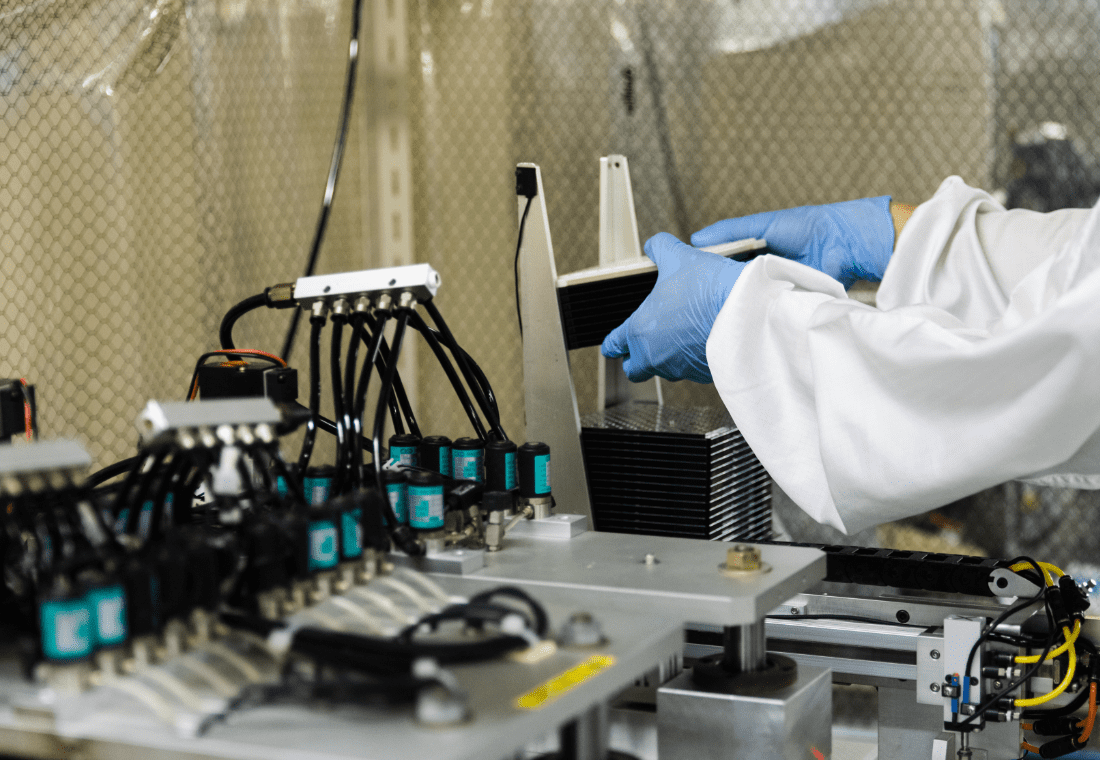

Automatic visual inspection machine (equipment developed in-house)

For products with metal cans with an outer diameter of up to φ9 mm stored in specially designated trays, we perform automatic 100% visual inspection according to the inspection standards (effective diameter, foreign matter, scratches, lens height, etc.) required by the customer.

We select the optimum lighting conditions and optical system for inspecting the products and make a pass or fail judgments by image processing.

Automatic leak inspection machine (equipment developed in-house)

We test products with an outer diameter of up to φ9 mm metal cans stored in specially designated trays for airtightness using automatic inspection equipment. The airtightness is judged by measuring the change in the degree of vacuum after sealing the inside of the products with negative pressure.

Yamamura Photonics owns various analysis devices for product performance evaluation.

In response to inquiries and requests from customers, the engineering department and the quality assurance department work together to analyze and investigate using analysis methods according to the content.

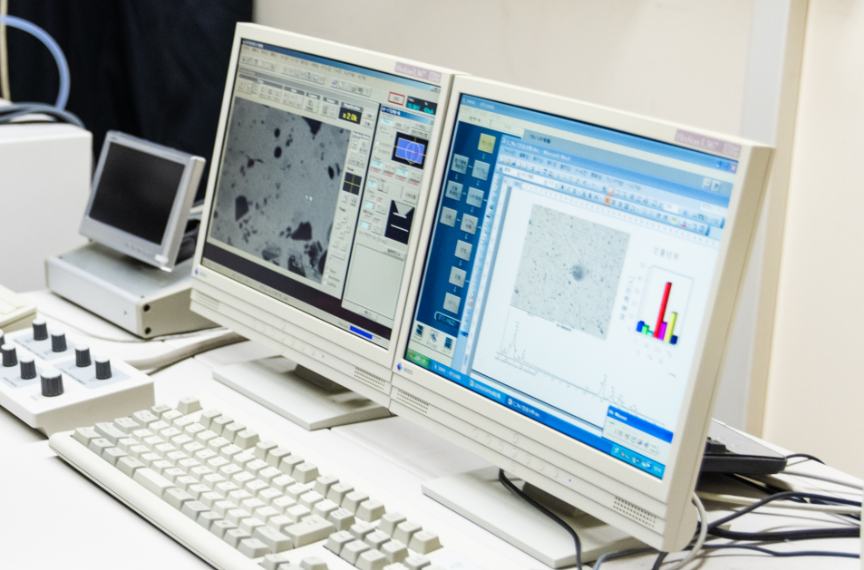

SEM/EDX

Metallurgical microscope

As the first step of investigation and analysis, we observe the appearance with SEM or metallurgical microscope, and we perform elemental analysis with EDX as needed.

Cross-section polishing equipment

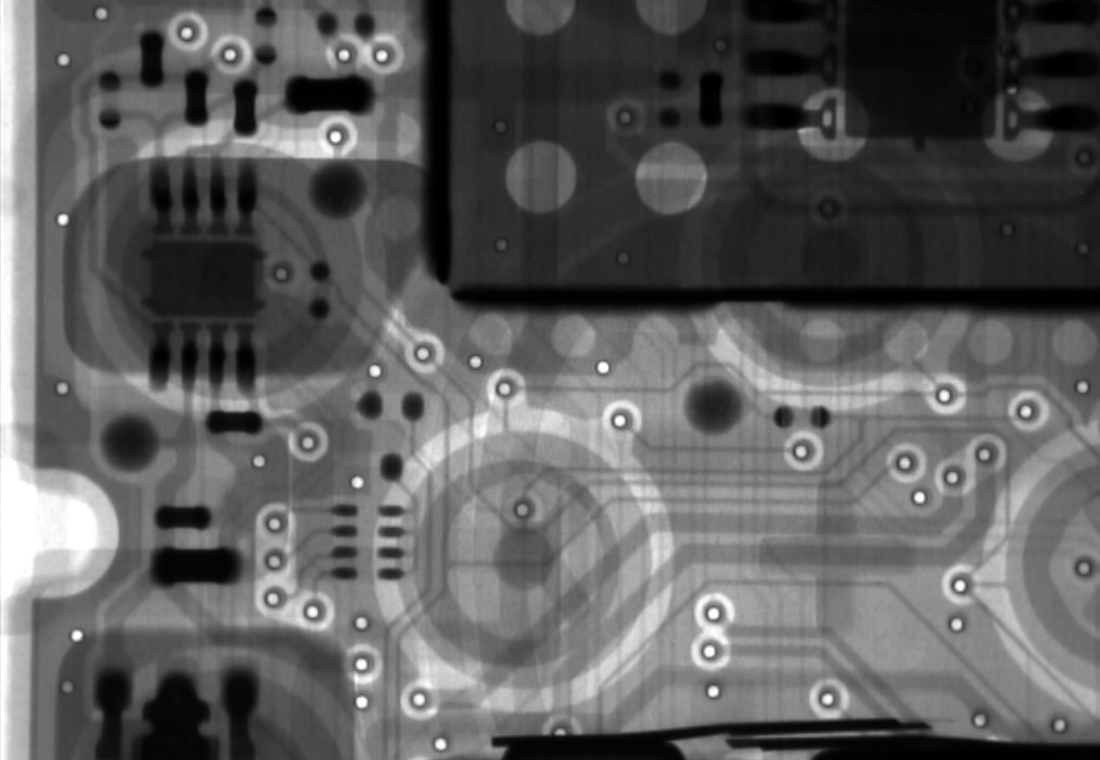

X-ray transmission device

To observe the inside of a part, we use the X-ray transmission device with the sample kept in the original condition, or we observe the cross section by cutting and polishing the sample.

Temperature cycle testing machine

High temperature and high humidity testing machine

To evaluate the reliability of the products, we carry out durability tests and accelerated deterioration tests that apply temperature and humidity loads.

He leakage detector

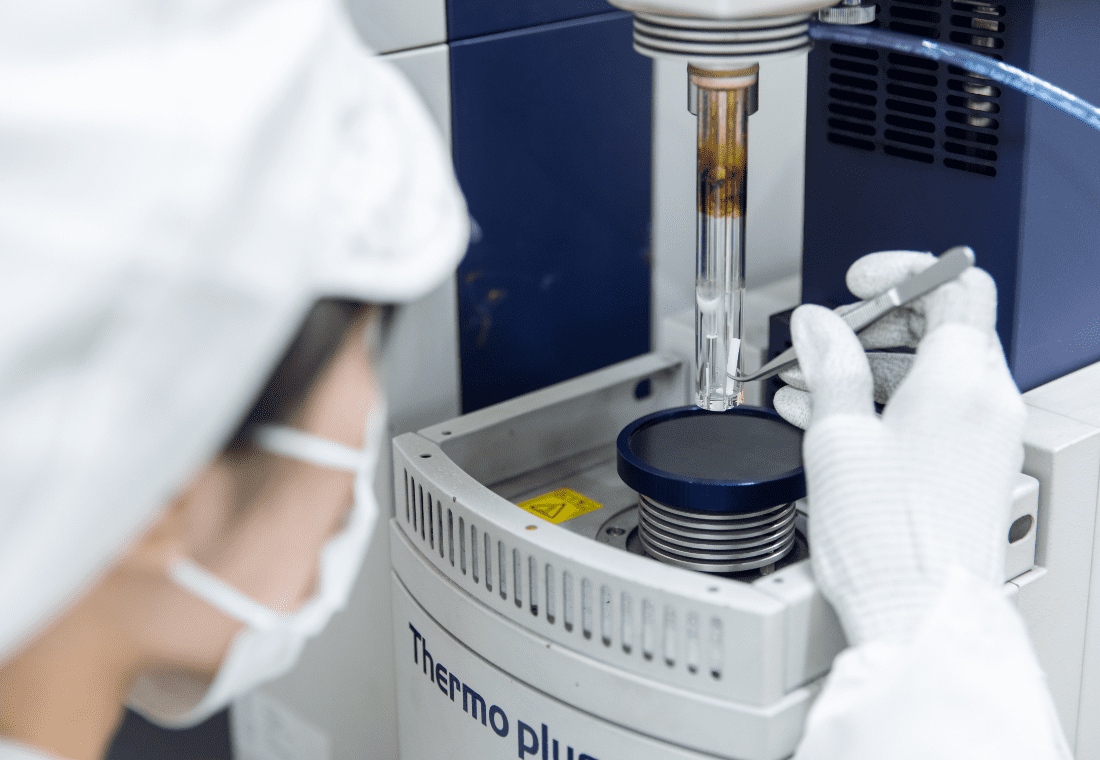

Spectrophotometer

X-ray fluorescence film thickness meter

We have devices to measure airtightness and optical characteristics, which are the main performances of hermetic products.

Thermomechanical analysis (TMA) equipment

Differential thermal analysis (DTA) Equipment

We have TMA, which measures the coefficient of expansion, and DTA, which analyzes changes in the sample due to temperature changes, as devices for measuring the thermal properties of glass and glass-ceramic sheets.

Particle size distribution measuring device

The particle size distribution is measured to evaluate the characteristics of glass powder and ceramic powder.

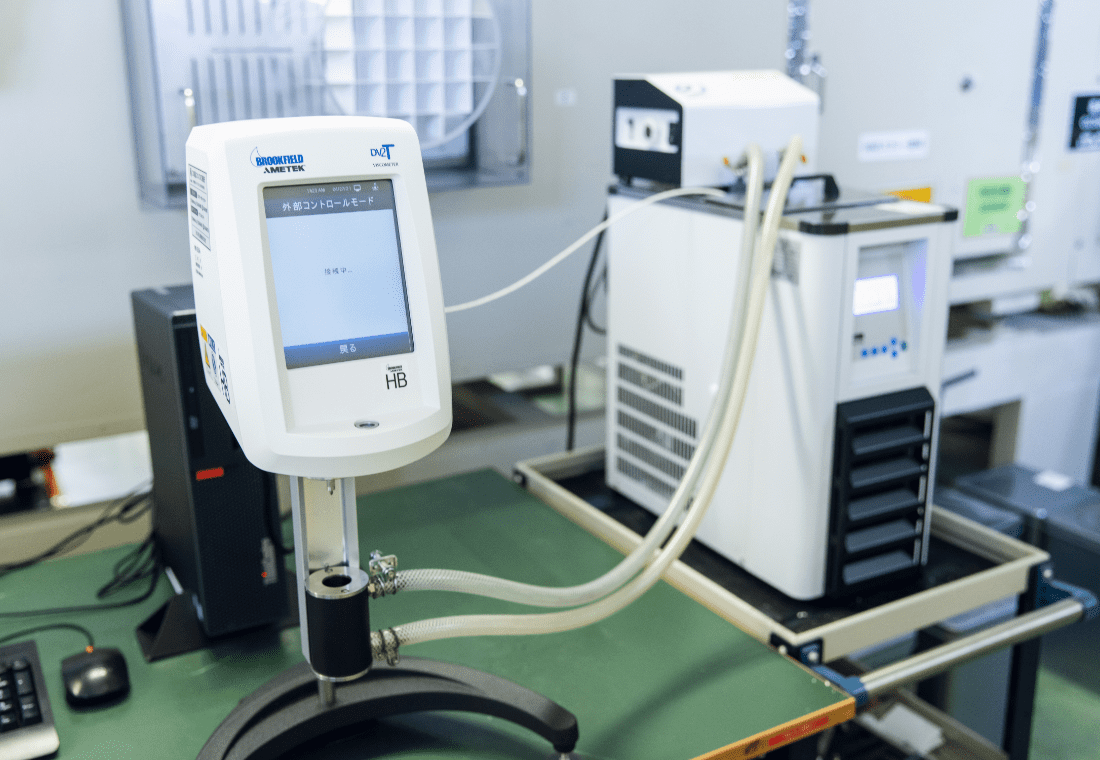

Brookfield viscometer

In the manufacturing process of glass-ceramic sheets, the viscosity of the slurry is controlled in order to maintain a constant film formation quality.

Polarimeter (strain measuring instrument)

Microscopic distortion tester

For large glass processed products, we supply highly reliable products by measuring the distortion of each product.