COLUMN

Dec 17, 2024

Relationship between green sheet thickness and shrinkage

The thickness of Yamamura Photonics green sheets can be adjusted. There are slight differences depending on the type, but in the case of standard GCS71 series part numbers, it is possible to produce sheets in the range of 30-300 µm (however, handling becomes more difficult in the case of thin and large sheets. For example, □500 mm x t30 µm).

In this article, we would like to introduce the relationship between green sheet thickness and shrinkage.

Shrinkage during sheet firing depends on the thickness of the green sheet.

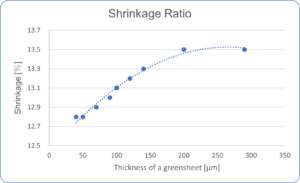

The graph below shows the mean XY shrinkage for different film thicknesses of the green sheet. The XY shrinkage rate increases as the film thickness increases, for example the mean shrinkage rate for a film thickness of 200um is 13.5%, whereas for a film thickness of 100um the mean shrinkage rate is 13.1% and for a film thickness of 50um the mean shrinkage rate is 12.8%. Comparing a sheet with a film thickness of 200um with a sheet with a thickness of 50um, there is a difference in shrinkage of 0.7%.

In the case of Yamamura Photonics’ green sheets, thinner film thickness tends to increase density and thicker film thickness tends to decrease density, resulting in this difference in XY shrinkage depending on film thickness (= green sheet density). When designing products using our green sheets, we would appreciate it if you could consider the influence of film thickness when designing products using our green sheets.