COLUMN

Nov 13, 2024

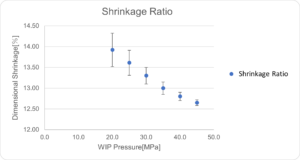

Relationship between press pressure and shrinkage during firing

In this issue, we look at the relationship between the press pressure used to stack green sheets and the shrinkage rate during firing.

When Yamamura Photonics green sheets are sintered into substrates, they shrink by approximately 13% in the XY direction, although there are slight differences depending on the type.

In general, the process for manufacturing multilayer ceramic substrates involves stacking and pressing multiple green sheets before placing them in a firing furnace for sintering. Yamamura Photonics uses the WIP (Warm Isostatic Press) method, in which the stacked green sheets are placed in a plastic bag to prevent submersion in water, and then placed in warm water in the WIP equipment and pressurised. Recommended conditions are 90°C or higher, pressure 35 MPa and press time 30 minutes.

Some equipment may not be able to achieve these recommended conditions. In practice, it is possible to produce a laminate from green sheets under conditions of approximately 70°C, 20 MPa pressure and a holding time of 15 minutes. However, the shrinkage rate and its variation will be higher than the recommended conditions.

The figure below shows data on the relationship between press (WIP) pressure and XY shrinkage measured using our green sheets. As the data shows, the higher the press pressure, the lower the shrinkage rate and the lower the variation. Comparing the XY shrinkage at the recommended conditions of 35 MPa and 20 MPa, the former is approximately 13 ± 0.3%, while the latter is approximately 13.9 ± 0.5%.

Since green sheets are supplied in a ‘raw’ state, some lot-to-lot variation is inevitable. In the firing process of LTCC, this relationship between pressure and shrinkage rate is used to adjust the shrinkage rate during firing by adjusting the press pressure and laminate density, thereby reducing the effect of lot-to-lot variation.