COLUMN

Jun 04, 2024

Important conditions for hermetic bonding of glass and metal (part 1)

1. Matching of thermal properties

When joining glass and metal, the most important factor is the matching of the thermal properties between the parts to be joined.

If the thermal properties of the metal and glass are not matched, stresses will occur due to expansion during heating and contraction during cooling, and depending on the magnitude of the stresses, the glass component may break. Even if the glass parts do not break immediately after bonding, there is still a possibility that they may break due to temperature differences in the operating environment or changes over time because of residual stresses.

So what should you be aware of?

Difference in average expansion coefficients

The first step is to compare the average expansion coefficients of the materials to be joined. The key point is that the difference in the average expansion coefficients of the materials to be joined should be within a certain range of values. For example, in the case of direct sealing using hard and soft glass with a glass transition point of approximately 450°C or higher, the difference in the average expansion coefficient α of the materials to be joined should be within α = ± 5 x 10-7/°C. In the case of joints using low-melting-point sealing glass, the difference in average expansion coefficient should be within α = +5 x 10-7/°C ~ -15 x 10-7/°C, and even more desirable, within 0 x 10-7/°C ~ -10 x 10-7/°C.

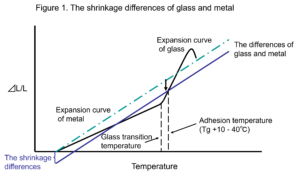

Shrinkage differences

The next step is to check the shrinkage differences of the materials to be joined in the range from the glass transition temperature and glass setting temperature (glass transition temperature +20-40°C) to room temperature. An easy way to see this shrinkage difference is to compare expansion curves measured using a thermo-mechanical analysis (TMA) machine. By shifting the expansion curve of the metal up to the sticking temperature and superimposing it on the expansion curve of the glass (see Fig. 1: green dotted line → blue solid line), the shrinkage difference can be visually identified. The width of the shrinkage difference, which can be seen by superimposing the expansion curves, is the stress that occurs when the members are heated to the sticking temperature, joined and then cooled to room temperature. The key to reliable bonding is to reduce residual stress by combining materials in such a way that the shrinkage difference is reduced.

Residual stresses in the glass part of a jointed component can be calculated using a polarimeter (polarimeter: a device that measures the interference fringes of glass by placing the glass between two orthogonal polarising or sensitive-colour plates). The safe residual stress guideline is below 6.7 MPa.