COLUMN

Sep 11, 2024

Temporal change of of LTCC green sheets

In this article we will look at temporal change of LTCC green sheets.

First of all, what does ‘green’ mean in green sheet? It doesn’t mean green!

The ‘green’ in green sheet means ‘raw’. It is called that because freshly made raw cheese is called ‘green cheese’. Therefore, green sheet means ‘raw’ sheet material before it is baked into a substrate.

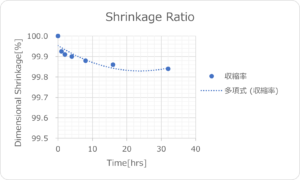

The green sheet is produced by making a slurry of ceramic and glass powders mixed with binders and solvents, forming it into a sheet and then drying it. After drying, the green sheet (product) contains approximately 0.1-0.5% residual solvent. The residual solvent affects the shrinkage rate when the sheet is fired, and if the proportion of residual solvent changes over time, the variation in shrinkage rate will increase and the dimensional stability of the substrate after firing will be compromised.

Yamamura Photonics recommends ageing before using LTCC sheets, as the effect of this variation is significant when they are used in precision equipment that requires miniaturisation and thinning.

Example: Recommended ageing conditions for GCS series green sheets (standard product)

Sheet condition: with carrier tape (PET film) peeled off

Temperature: 18-25°C

Humidity: 30 – 70%.

Environment: Clean environment

Time: 8 to 24 h

Aging can stabilise the shape and shrinkage rate, as well as prevent wire breakage due to via misalignment.