PRODUCTS

OPTICAL PARTS

LED Packages Glass LIDs

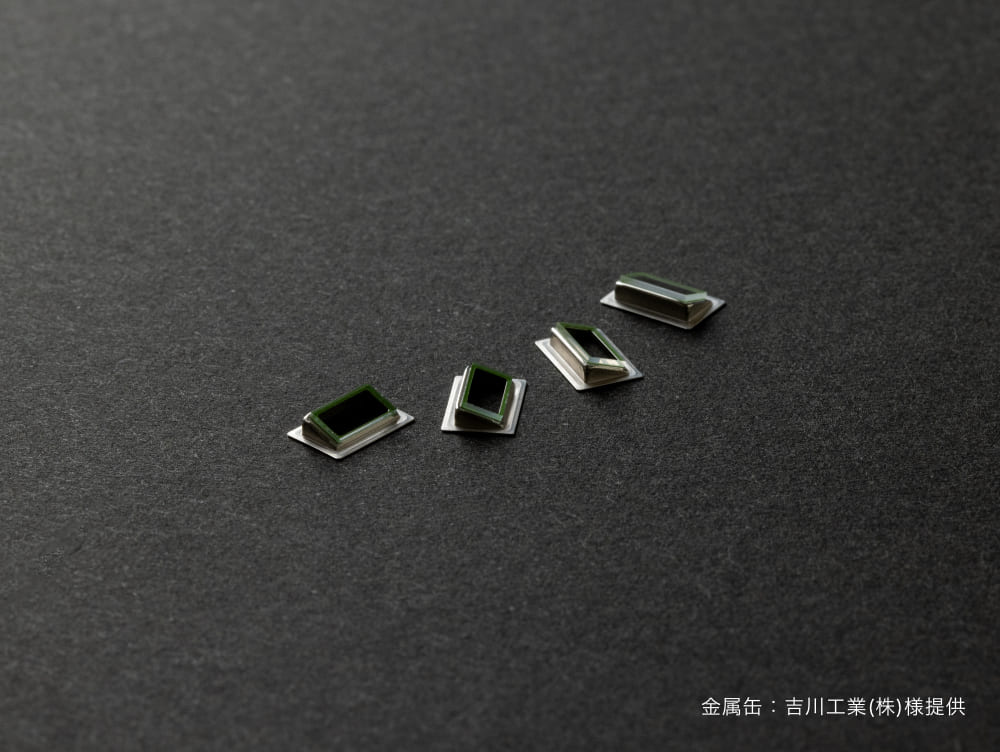

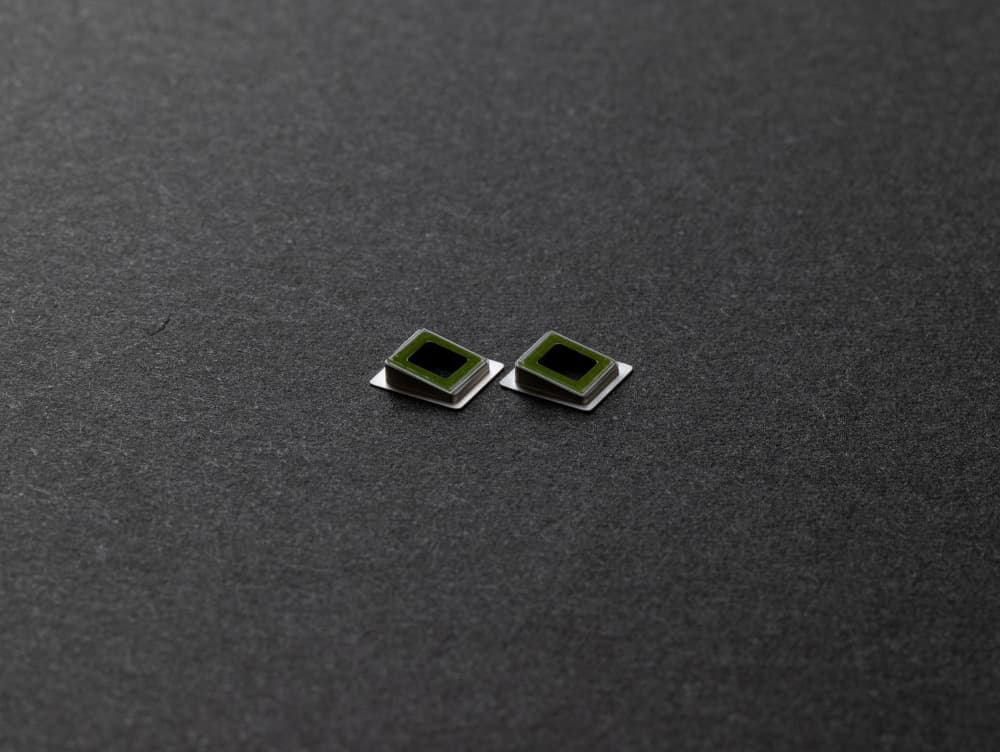

Seam-Welded Glass LIDs

OUTLINE

The seam welding type is designed with a thin metal frame flange thickness and can be joined to the cavity by seam welding. We propose custom-designed products, and we can handle from small ones with a size of a few mm up to a large one with a size of several tens of mm. In addition, it is possible to handle shapes such as tilting windows, which contributes to measures against return light.

FEATURES

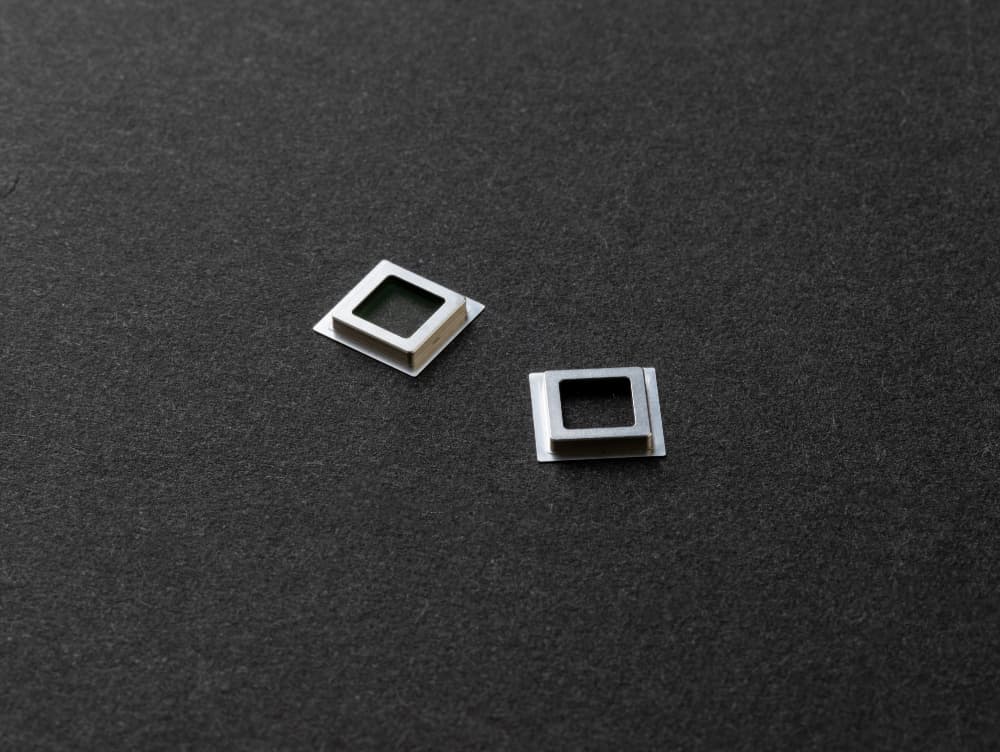

Two types of joining methods

Yamamura Photonics has two types of joining methods of glass and metal frames.

・Sealing glass type

A standard type joined using sealing glass. We select window materials and metals according to the application. Sealing glass type Lids are used in a wide range of applications such as LEDs, MEMS packages, and LiDAR.

・Directly joined type

A type in which the window material and the metal frame are directly joined without sealing glass. The height can be reduced because of its fewer parts, but the choice of window material and metal material is limited in this type. The directly joined type Lids have been adopted mainly for LED packages.

Custom design support

We can provide custom designs, including optical coatings for ultraviolet rays and mid-infrared applications. We propose the optimum design according to the application and required characteristics.

Size: □ 3mm ~ □ 26mm

Frame Material: Kovar, 50FeNi

Window Material: Borosilicate glass, UV transparent glass, quartz, sapphire, Ge

Optical design

Ultraviolet/Infrared Packages/LIDs

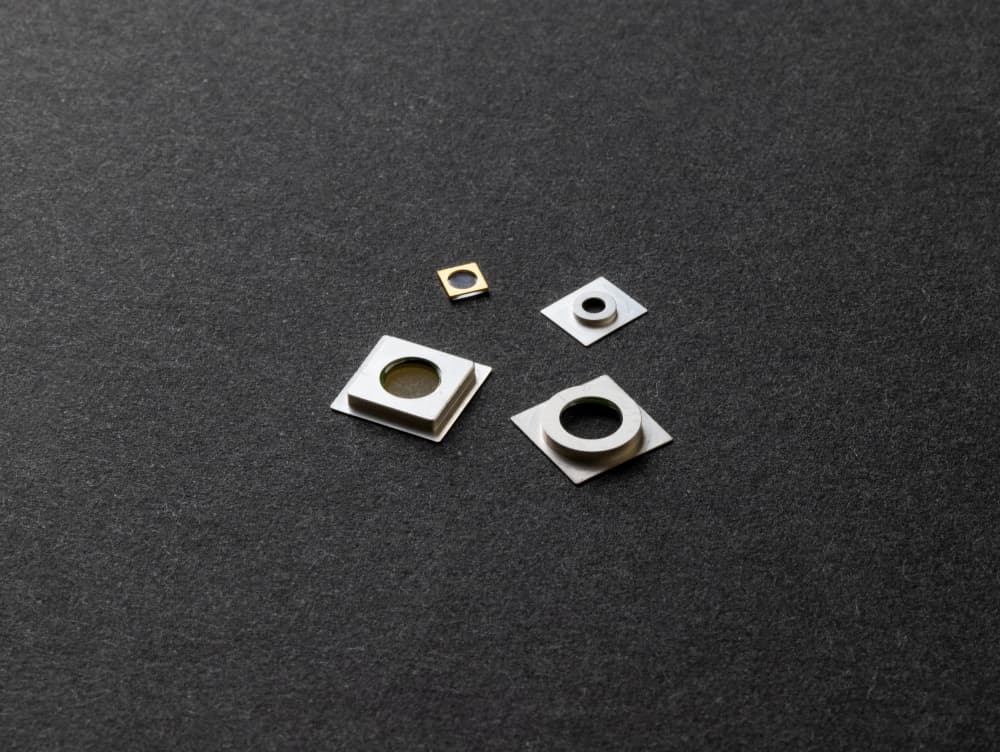

Design achievements of various shapes

Through the experience of providing custom designs according to the application, we have products with various shapes such as square or rectangular frames, round and square windows, and stepped shapes, etc. In addition, we can provide tilted window products.

Standard Samples

coming soon